Introduction:

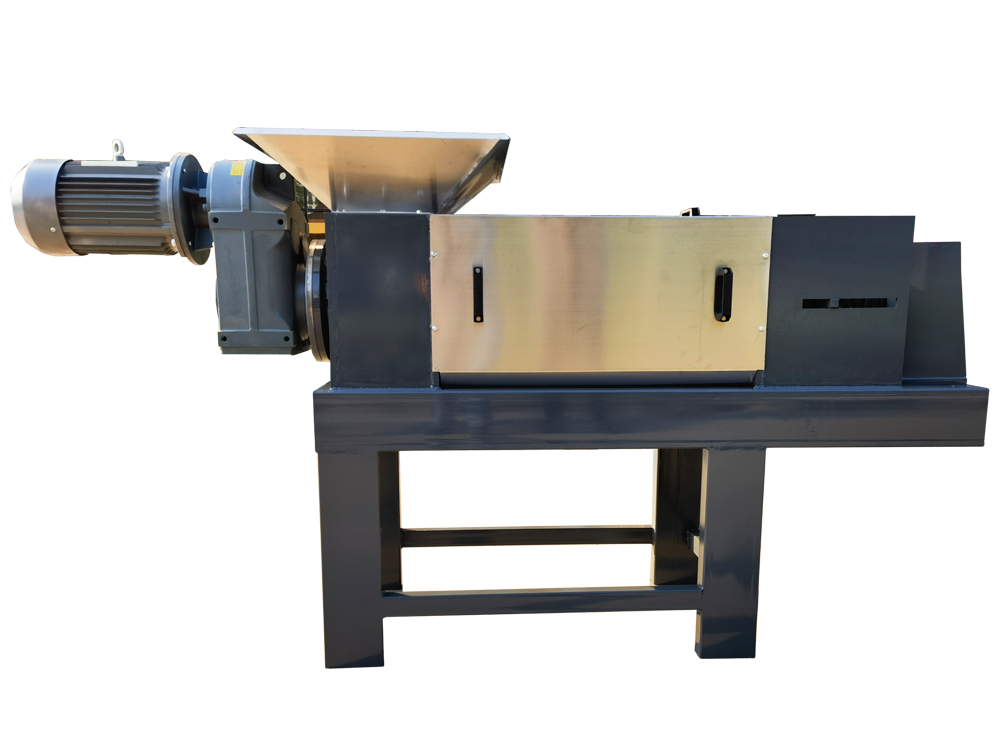

Screw dewatering presses play a pivotal role in various industries by facilitating efficient solid-liquid separation processes. These innovative machines utilize a screw mechanism to remove moisture from sludge, contributing to the reduction of waste volume and the extraction of valuable resources. In this article, we will delve into the working principles, applications, and benefits of screw dewatering presses.

Working Principles:

The core functionality of a screw dewatering press lies in its ability to apply mechanical pressure to sludge, forcing water to separate from solid particles. A rotating screw within the press chamber gradually compresses the sludge, squeezing out water through a filtering system. This process results in drier solids and a significant reduction in sludge volume.

Applications:

Municipal Wastewater Treatment Plants:

Screw dewatering presses are extensively used in municipal wastewater treatment plants to process sewage sludge. By efficiently removing water content, these presses aid in the production of sludge with higher solids concentration, reducing disposal costs and environmental impact.

Industrial Processes:

Industries generating wastewater or sludge as a byproduct, such as food processing, pulp and paper, and chemical manufacturing, benefit from screw dewatering presses. These machines contribute to the effective management of industrial waste by extracting water and facilitating proper disposal or resource recovery.

Agricultural Residue Treatment:

Screw dewatering presses find applications in agricultural settings for processing organic materials like manure. By separating water from organic solids, these presses assist in the creation of nutrient-rich fertilizers and contribute to sustainable agricultural practices.

Benefits:

Cost-Efficiency:

Screw dewatering presses help industries and municipalities save on disposal costs by reducing the volume of sludge. The drier solids obtained are often easier and more cost-effective to transport and dispose of.

Resource Recovery:

The separated water can be treated and reused, promoting water conservation. Additionally, the dewatered solids can be repurposed for applications such as soil conditioning or energy generation.

Environmental Impact:

By minimizing the volume of sludge and efficiently managing waste, screw dewatering presses contribute to a more sustainable and environmentally friendly approach to wastewater and sludge treatment.

Conclusion:

Screw dewatering presses have become indispensable in modern waste management and water treatment practices. Their ability to enhance solid-liquid separation, coupled with the myriad applications and environmental benefits, positions them as valuable assets across various industries. As technology continues to advance, these presses are likely to play an even more significant role in shaping sustainable and efficient waste management solutions.

TEL:+86 17753651813

TEL:+86 17753651813

EMAIL:liumeifang@chuantaimc.com

EMAIL:liumeifang@chuantaimc.com

WeChat:17753651813

WeChat:17753651813

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China

Copyright © 2022-2024 Chuantai Machinery, INC. All Rights Reserved.

sitemap Screw Press Dewatering Machine